旋削加工機A型

特 徴

- A型チャックは頭部を飛び越して、軸部をチャックするため、軸部との偏心が無く、高い精度の加工が可能です。

- 各交換用カムは、切削仕様変更時に4本のボルト着脱により、カム交換が簡単にできます。

- 製品供給用スクイアゲホッパーおよびレールシュートは様々な圧造品を対象として、使用できます。

- D型孔明けにおいては、ワークおよびドリルが対向回転で孔明けできるため、また、ドリル回転インバータ装置、ドリルユニットステップ装置(任意反復運動、タイマー制御)により、 制度の高い深孔明けが可能です。(孔明能力:1.5〜Φ10×最大深さ40mm)

ENGLISH

ENGLISHA TYPE JAW CHUCK SPECIAL FEATURES

- It is possible for A type machines to process parts precisely without eccentricity to the parts shaft by over-head chucking parts.

- It is easy for operaters to change cams by removing and fastening 4 bolts in tooling changes.

- It is possible that a standard hopper and rail chute for supplying parts are used for many kinds of cold-formed parts.

-

It is possible for AD type machines to drill parts deeply with high precision with a main spindle facing a drilling spindle each other and by using a drill-turning control inverter and drill-stepping function.

drill-stepping : optional movement by timer control

drilling limit : φ1.5~φ10×40mm depth

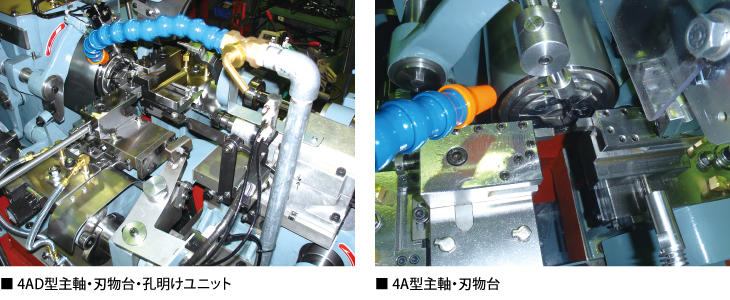

MODEL TO-4AD : MAIN SPINDLE・TOOL SLIDES・DRILLING UNIT

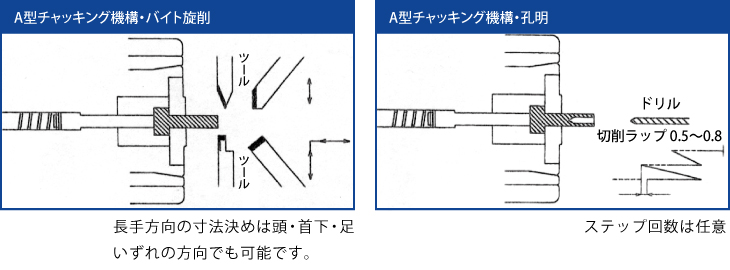

MODEL TO-4A : MAIN SPINDLE・TOOL SLIDES A TYPE CHUCKING MECHANISM・ARRANGEMENT OF CUTTING TOOLS

TOOLS

It is possible to choose the positions to be shaved in all the positions,head side,under head and opposite side to head that can be chosen as chuchking points.

A TYPE CHUCKING MECHANISM・DRILL MOVEMENT

STEPPING INTERVAL 0.5~0.8

The numbers of stepping times are optional.

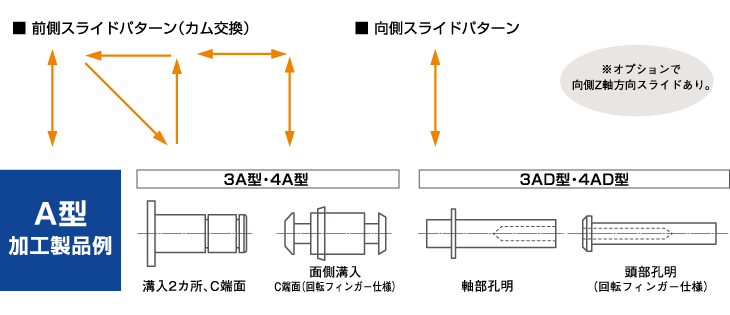

TOOL SLIDES MOVEMENT PATTERNS

2 TOOL SLIDES FACED EACH OTHER、4 TOOLS、FRONT TOOL SLIDE MOVEMENT PATTERN(CHANGE CAMS)

REAR TOOL SLIDE MOVEMENT PATTERN

*REAR Z AXIS MOVEMENT SLIDE IS OPTIONAL.

PROCESSED PARTS SAMPLES

2 GROOVING,C CHAMFERING & FACING

GROOVINGS,C CHAMFERINGS & FACINGS (WITH TURNING FINGER)

DRILLING TO PARTS SHAFT END BY OVER-HEAD CHUCKING

DRILLING TO PARTS HEAD END BY UNDER-HEAD CHUCKING(WITH TURNING FINGER)